about

- Top

- About

The current production of steel from iron ore requires fossil resources such as coal, which emits CO2.

As CO2 emissions resudtion is further persued on a global scale, the Japan Iron and Steel Federation is taking on the challenge of developing innovative technologies to achieve its carbon neutrality.

Global Warming

Global Warming and CO2

Greenhouse gas (GHG) is said to be one of the causes of global warming. Many carbon-based gases are included in GHG but CO2 (carbon dioxide) is the one that is emitted in overwhelmingly large quantities due to human activities and is considered to have the greatest impact on global warming.Since the industrial revolution, the use of fossil fuels such as coal, oil, and natural gas has increased, and as a result, the amount of CO2 emitted into the atmosphere has also increased.

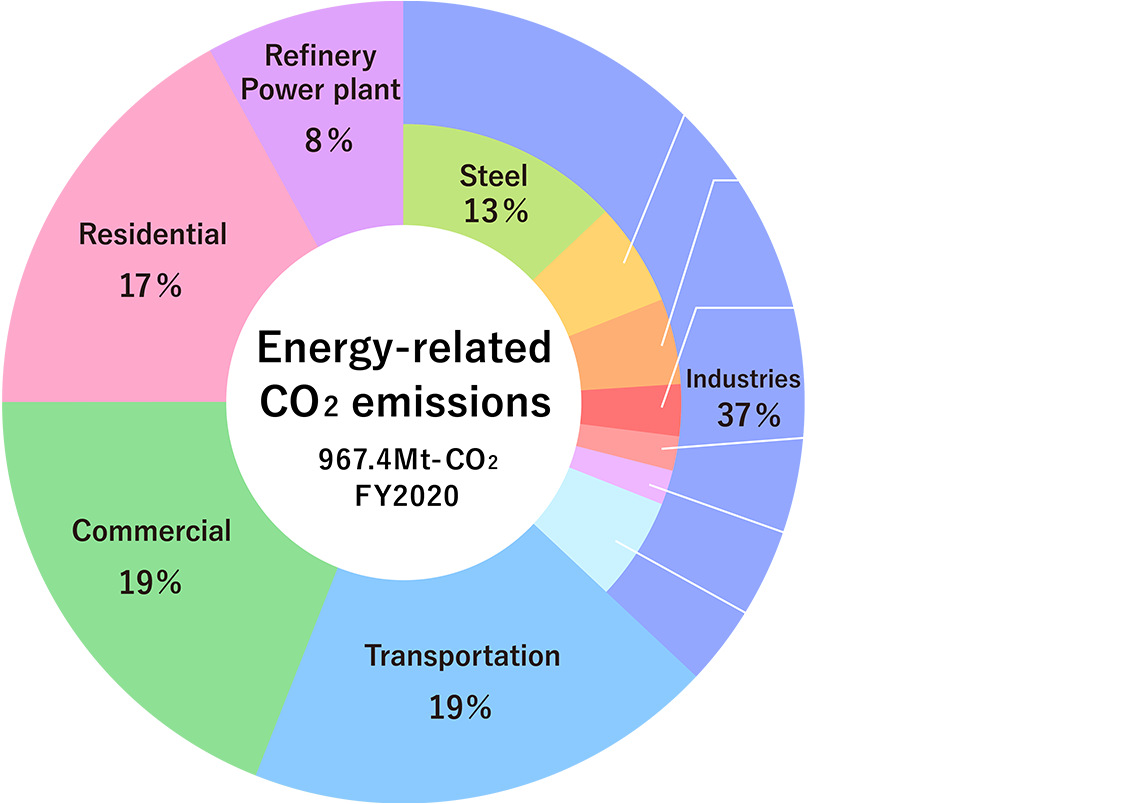

The steel industry, in particular, is one of the largest emitters of CO2 among Japan’s industrial sectors due to its large manufacturing volume, and reducing its emissions is an important issue.

Energy-related CO2 emissions from in Japan (FY2020, fuel combustion emissions allocated to energy consumers)

* You can see the figure enlarged.

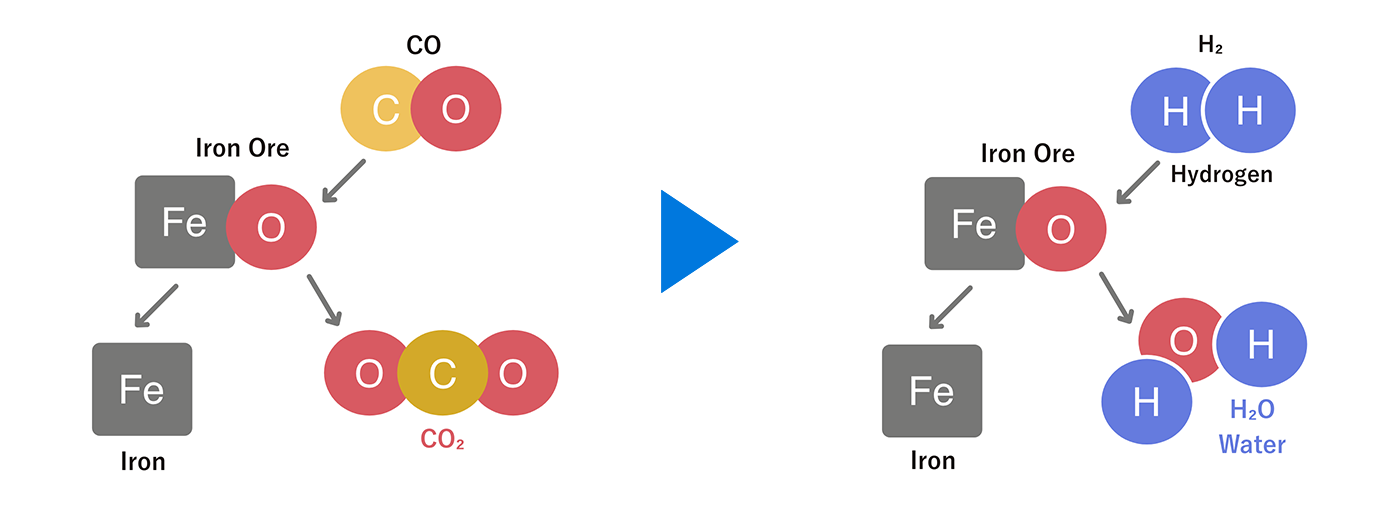

Conventional steel production

Iron and steel are made from iron ore, which is like a rust, where iron (Fe) is bound to oxygen (O) in the air. In order to produce iron from iron ore, oxygen have to be stripped away. Carbon (C), which is contained in fossil fuels such as coal, is currently used as a reducing agent. Carbon binds to oxygen more strongly than iron, so it removes oxygen away from iron ore. This reaction is called “reduction”. The reduction of iron ore with carbon produces iron and CO2.

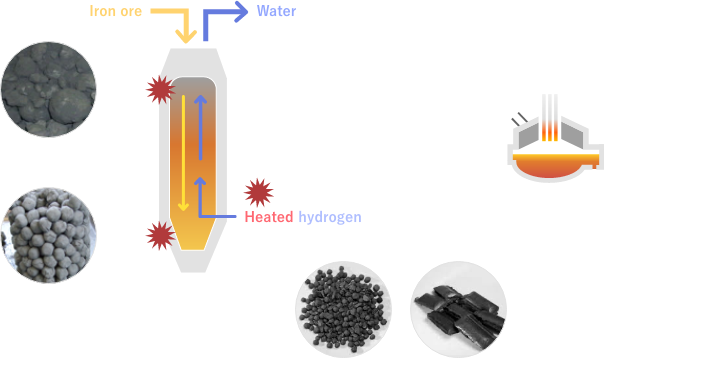

Steel production with hydrogen

Like carbon, hydrogen gas (H2) is easily combined with oxygen, so hydrogen can also be used to reduce iron ore. When hydrogen is used to reduce iron ore, H2O (water) is produced along with the iron. Therefore, if hydrogen can be used to reduce iron ore, CO2 emissions in steel production will be eliminated, and carbon neutral steel will be realized.

Iron ore reduction with carbon

Iron ore reduction with hydrogen

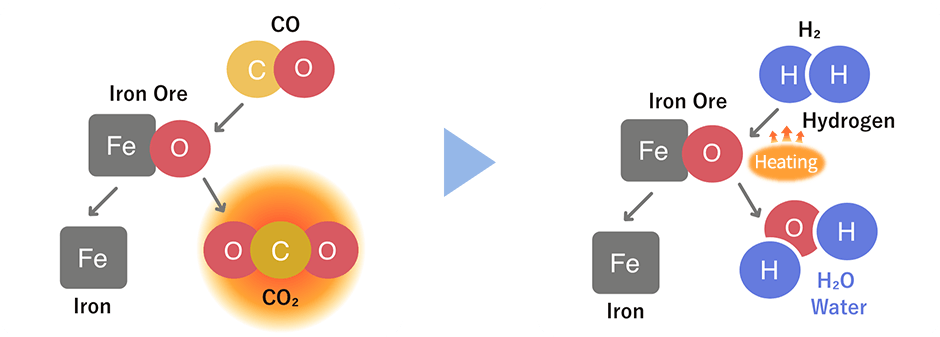

Challenges of hydrogen use in steel production

However, steel production with hydrogen is not easy due to the following reasons.(1) Reduction with hydrogen cools down the process.

The conventional reduction of iron ore by coal is an exothermic reaction, which is very convenient because the iron melts out as the reaction proceeds. On the other hand, the reduction of iron ore by hydrogen is an endothermic reaction that requires heat, so the reaction cannot proceed unless the hydrogen is heated.The technology to heat a large amount of explosive hydrogen gas to a high temperature is a technology that is not exist now, and requires the development of technology with very high hurdles.

Iron ore reduction with carbon

Iron ore reduction with hydrogen

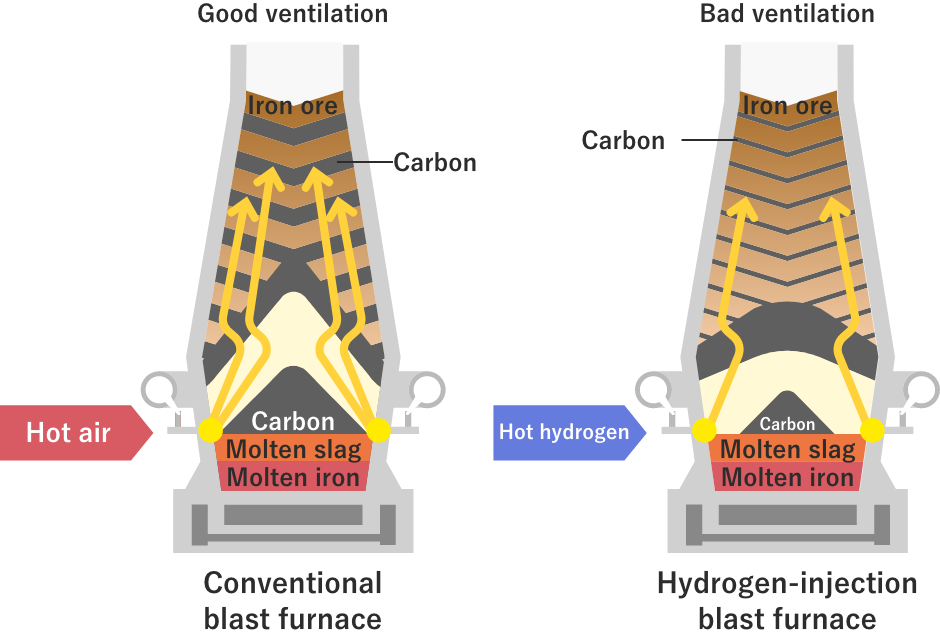

(2) Conventional blast furnace is not easily applicable to hydrogen based steel making.

The current steel making process is carried out in a huge reactor called a blast furnace, which is about 100 meter high. Iron ore and coal are alternately applied and stacked in the blast furnace, and high-temperature air is blown from sides below. Then, iron ore is reduced in the blast furnace, producing iron and emitting CO2. In this process, the coal does not burn, but acts as reducing agent of iron ore, and also plays an important role in supporting the iron ore as a solid and maintaining ventilation inside the blast furnace.On the other hand, when coal is replaced with hydrogen gas, this solid support is lost. So, there is a limit to the amount of hydrogen that can be input to a blast furnace, because adding hydrogen to the conventional blast furnace method means reducing the amount of coal.

The blast furnace is an extremely energy efficient and productive iron ore reduction furnace with a history of several hundred years, and the majority of the world’s iron is made by this method. However, it is an extremely huge reactor, and its production costs tens of billions of yen. The major technical issue is how much hydrogen can be input to the blast furnace in the conventional blast furnace.

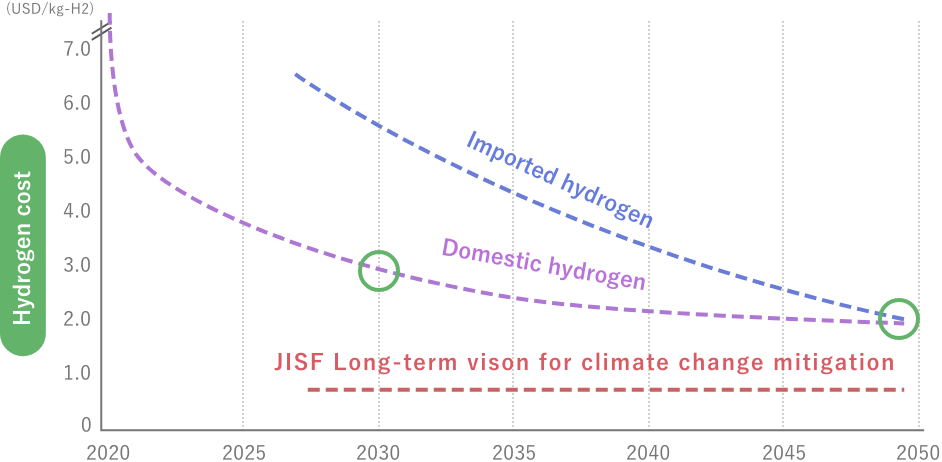

(3) Use of large quantities of inexpensive carbon-free hydrogen

Coal can be obtained by digging coal mines, but hydrogen gas is not available from earth, and must be produced artificially. However, the use of hydrogen has so far been limited to a few industries, and there is currently little social infrastructure to supply large amounts of hydrogen in wide area.In addition, most hydrogen production has so far been made from fossil fuels, and CO2 is also generated during hydrogen production. The hydrogen used for carbon neutral steel is meaningless unless it is also CO2-free during its production (carbon-free hydrogen).

Furthermore, since steel is a basic material that is used in large quantities everywhere in the world, the hydrogen used in its production must also be inexpensive.

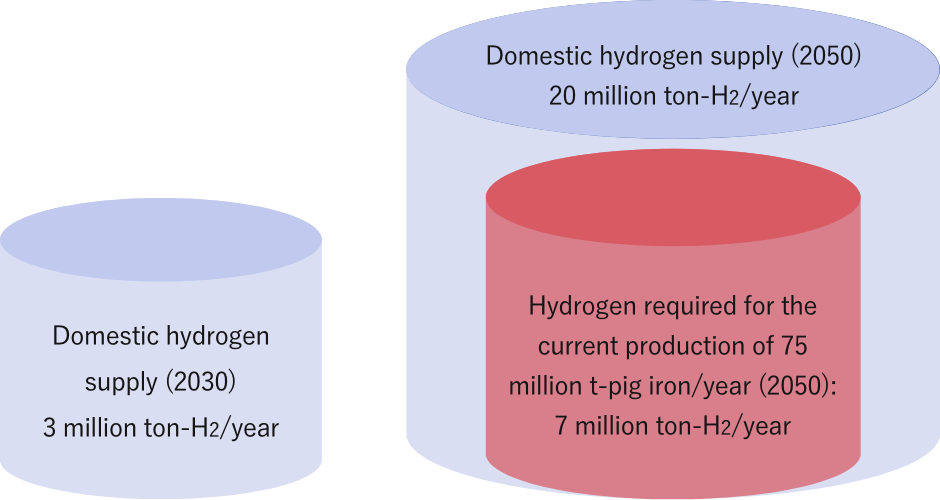

In other words, in order to realize carbon neutral steel, it is also essential to develop a infrastructure that can supply large amounts of inexpensive carbon-free hydrogen.

Perspectives of hydrogen price and supply in Japan (Green Growth Strategy towards 2050 Carbon Neutrality, 2020) (circle), and perspective of hydrogen cost trend (broken lines)

* You can see the figure enlarged.

Domestic hydrogen supply in the Strategy

* You can see the figure enlarged.

Challenges towards Carbon Neutrality

Although there are various challenges towards carbon neutrality as described above, the Japan Iron and Steel Federation will take the following steps to realize it.

(1) Challenge from COURSE50 to Super COURSE50

In order to implement iron making partially with hydrogen in blast furnace even in the current situation where there is no external infrastructure for mass hydrogen supply, In COURSE50 project 10% of hydrogen is input the blast furnace using the by-product hydrogen gas produced in an integrated steel plant currently used in furnaces and power plants and accordingly decreasing the amount of carbon input to the blast furnace.In the medium to long term, however, a sufficient external hydrogen supply will be available. At that time we will be able to purchase hydrogen from outside the steel plant and we will be able to input more hydrogen into the blast furnace. In response, we will take on the challenge of achieving carbon neutral steel, which means reducing the amount of carbon input to the blast furnace to the limit.

As mentioned above, Super COURSE50 cannot reduce the supporting carbon to zero since because blast furnace is used. Therefore, it is necessary to develop technologies to reduce the remaining CO2 emissions by combining CCUS (CO2 Capture, Utilization and Storage). Particularly in the case of CCS (CO2 Capture, Utilization and Storage), it is also necessary to develop storage sites as an infrastructure.

(2) Challenge of hydrogen-based ironmaking

In order to completely reduce iron ore solely with hydrogen, beyond the limit of hydrogen use in Super COURSE50, a totally different iron ore reduction technology that does not use a blast furnace is required.A possible iron making that does not use coal is the direct reduction of iron ore, which uses natural gas (methane) as a reducing agent. With this technology iron ore is reduced without the support of coal (but does not melt it, producing solid iron with gangue), and there is a possibility to produce iron using 100% hydrogen, so called ‘hydrogen-based ironmaking’.

However, when 100% hydrogen is applied, the iron ore is tend to become powdery and clogged. In addition, as the reduction of the iron ore proceeds, the iron stick to each other (sticking) and cannot be removed from the furnace. In order to prevent these problems, only a limited type of iron ore can be used at present. Therefore, a complete hydrogen-based ironmaking does not yet exist today.

However, the Japan Iron and Steel Federation believes that hydrogen-based ironmaking is essential to achieve carbon neutraIty, and will continue to take on the challenge of developing this technology.

The challenge to carbon neutrality includes the challenges to develop all of these technologies.

* You can see the figure enlarged.